Hook And Loop Sanding Discs vs Stick On Sanding Discs

When it comes to heavy sanding applications with an orbital sander, stick on discs were the disc of choice for many years. But as technology has advanced, these are now becoming antique. The great thing with adhesive backed discs is they stuck, they did not fly off, it made them reliable. The main downside was they created a lot of dust and there is not an easy or efficient way to contain this dust.

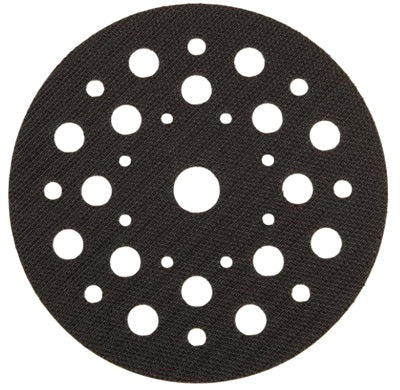

Technology with sanding discs has moved to velcro or hook and loop backed abrasives and now rather than being a solid disc they have multiple holes or in some cases they are just made from mesh, but the main question / complaint I get is...

Why cause's my sanding discs to not stick on my sander?

The main reason for discs not sticking is because of a worn out back up pad.

The back up pad has nylon hook and loop to receive and hold the discs in place, when this gets really hot during the sanding process these soften and melt and have less and less holding power until they get to the point where the disc no longer sticks and flies off.

When it comes to using power sanders there are a few things that need to be understood to get the best out of the machine, the abrasive and the surface being prepared.

Here are several things you can do to get the best out of your sander:

1/ Get a Pad Saver, this is a heavy duty, very high quality hook and loop sacrificial pad that protects the bup pad from premature failure, they are cheap yet exceptionally effective.

2/ Connect to a vacuum or dust extractor. This has multiple benefits:

a/ It sucks away the dust, physically removing it, meaning you are sanding the surface that needs to be sanded. If you don't remove it, you keep going over the dust, pushing it back into the surface effectively re sanding the same material.

b/ The airflow keeps the back up pad cool, this means the hook and loop are much less likely to get overheated, soften and melt.

c/ The airflow also keeps the surface you are working on cool and helps reduce clogging and pilling.

d/ Abrasives used with dust extraction will last on average 30% longer than discs with no extraction.

e/ Dust extraction will increase productivity significantly, meaning much less time sanding which not only makes you more money, but it also saves wear and tear on your tools.

3/ Let the sander do the work, pressing harder will fatigue the user, the tool and the consumable. The sander should be allowed to spin freely, which allows the orbital action to work properly.

4/ Once your back up pad is beyond resurrection, get a pad saver and glue it on with contact adhesive and you will get some more life before having to succumb to replacing it.

Happy Sanding!

*Originally Posted by Matt Piggin on 28th Nov 2018